The best waste disposal equipment

RDF EQUIPMENT is the most advanced waste-derived fuel production facility for the production of combustible waste and biomass fuels

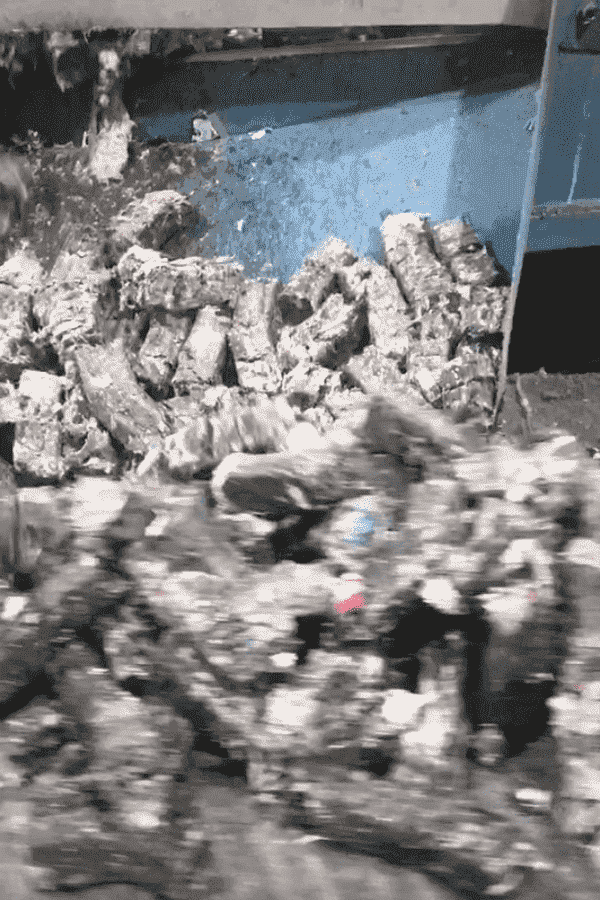

Efficient crushing ability

Shredding machines possess powerful crushing capabilities, capable of quickly and effectively crushing various materials, greatly improving work efficiency.

Packed with features & gadjets

Pork belly portland fingerstache pitchfork dreamcatcher, retro lo-fi deep v chillwave fixie kitsch bitters

Made for professionals

Pork belly portland fingerstache pitchfork dreamcatcher, retro lo-fi deep v chillwave fixie kitsch bitters

Easy to operate, high production efficiency

Stable high output is the ideal choice for factories

Can handle multiple raw materials

Can produce a variety of raw materials, with a wide range of applications

20 consecutive hours of uninterrupted work

Continuous production without stopping to add lubricating oil

Production video

Various raw material production videos

Features

Functions of molding equipment

Manual/Automatic lubrication oil refilling

Automatic lubrication without stopping operation

Forming modules & rollers are repairable and reusable.

The host machine can be configured for interlock operation with the feeding conveyor and silo.

Material feeding will automatically halt upon overload current and restart after normal current is restored.

The mold orifices are customizable

with square, rectangular and circular configurations available based on material specifications and production needs.

Our forming machinery comes in various configurations

offering throughput capacities from 1TPH to 5TPH (tons per hour) per standalone unit. The system supports multi-unit parallel operation for scaled-up production.

Important: Throughput varies according to feedstock characteristics.

Typical output ranges are based on standard materials under optimal conditions.

Revolutionary features